Линейный регулирующий клапан Flowserve MARK ONE, угловой клапан

Обзор продукта

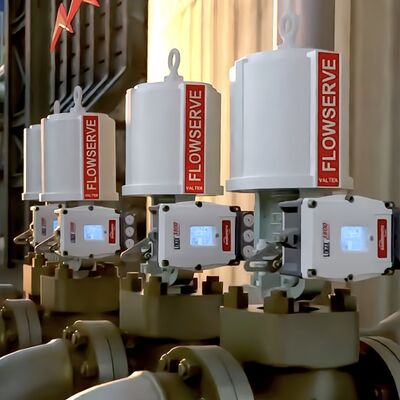

Регулирующий клапан Flowserve Mark One Linear Globe Angle Control Valve - это универсальный и высокопроизводительный регулирующий клапан, предназначенный для точного регулирования расхода, давления, температуры и уровня в промышленных технологических системах.

Созданный с прочным корпусом и гибкими вариантами исполнения, клапан Mark One обеспечивает надежную работу в широком спектре применений, включая жидкости, газы и пар.

Серия Mark One включает в себя как линейные шаровые и угловые конфигурации корпуса, предлагающие превосходные дроссельные характеристики, отличную стабильность управления и надежную герметичность. В сочетании с пневматическими или электрическими приводами и цифровыми позиционерами клапанов он становится комплексным решением для автоматизированного управления технологическими процессами.

Клапаны Flowserve Mark One обычно используются на химических заводах, в нефтегазопереработке, энергетике, водоочистке и в общей промышленной автоматизации.

Основные характеристики

Линейные шаровые и угловые корпуса клапанов, подходящие для различных технологических условий

Точное дроссельное регулирование и высокая регулируемость

Несколько материалов корпуса и вариантов исполнения для индивидуального обслуживания

Прочная конструкция для длительного срока службы и снижения затрат на техническое обслуживание

Совместимость с пневматическими мембранными и поршневыми приводами

Поддержка цифровых и электропневматических позиционеров клапанов для расширенного управления

Надежная герметичность

Широкий диапазон размеров и классов давления

Предназначен как для новых установок, так и для модернизации

Легкий доступ к внутренним компонентам для технического обслуживания

Технические характеристики

Тип клапана

Линейный шаровой регулирующий клапан

Угловой регулирующий клапан

Материалы корпуса

Углеродистая сталь

Нержавеющая сталь

Сплавная сталь

Материалы исполнения

Нержавеющая сталь

Закаленные сплавы для тяжелых условий эксплуатации

Концевые соединения

Фланцевые

Сварные

Класс давления

ANSI Class 150, 300, 600, 900, 1500 и выше (в зависимости от модели)

Характеристики потока

Линейный

Равнопроцентный

Размеры клапанов

Стандартный промышленный диапазон номинальных диаметров

Совместимость с приводами

Пневматические мембранные приводы

Пневматические поршневые приводы

Электрические приводы

Совместимость с позиционерами

Цифровые позиционеры клапанов

Электропневматические позиционеры

Диапазон температур

Подходит для стандартных и высокотемпературных промышленных процессов

Применение

Регулирование расхода в химической и нефтехимической переработке

Регулирование пара в энергетических и коммунальных системах

Регулирование давления и температуры на нефтегазовых заводах

Водоснабжение и распределение сточных вод

Автоматизация технологических процессов в фармацевтической и пищевой промышленности

Общие системы управления промышленными процессами

Преимущества

Обеспечивает стабильное и точное регулирование процесса

Повышает общую эффективность системы и качество продукции

Снижает изменчивость процесса и повышает безопасность

Поддерживает интеграцию с интеллектуальными системами автоматизации

Прочная конструкция сводит к минимуму время простоя

Гибкие конфигурации охватывают широкий спектр промышленных применений

Как это работает

Регулирующий клапан Mark One использует механизм пробки и седла для регулирования потока технологической жидкости.

Когда привод получает управляющий сигнал, он перемещает шток клапана, позиционируя пробку относительно седла.

Это движение изменяет траекторию потока и управляет интересующей переменной, такой как скорость потока, давление или температура.

При оснащении цифровым позиционером клапана клапан обеспечивает точное позиционирование и быструю реакцию на изменения управляющих сигналов.

Обзор установки

Установите клапан в правильном направлении потока в соответствии с маркировкой корпуса

Закрепите привод и позиционер, используя соответствующий монтажный комплект

Подключите провода управляющего сигнала или пневматическую трубку

Проверьте подачу воздуха и соединения контура управления

Выполните калибровку и испытание хода

Проверьте работу клапана в нормальных условиях

Часто задаваемые вопросы

С какими средами может работать клапан Mark One?

Клапан Mark One может работать с жидкостями, газами и паром в зависимости от выбранных материалов и исполнения.

Какие конфигурации доступны?

Он предлагает как линейные шаровые, так и угловые типы корпуса с различными материалами корпуса и вариантами исполнения.

Можно ли его автоматизировать?

Да. Он совместим как с цифровыми, так и с электропневматическими позиционерами клапанов и приводами.

Подходит ли он для высоких температур?

Да. При правильном выборе материалов и изоляции он надежно работает в условиях повышенной температуры.

Как часто требуется техническое обслуживание?

Прочная конструкция клапана и легкий доступ к внутренним компонентам помогают свести к минимуму частоту технического обслуживания.

Сопутствующие товары

Регулирующий клапан Flowserve Valtek Mark Two

Регулирующий клапан Flowserve Valtek Mark Three

Цифровые позиционеры клапанов Flowserve Logix

Шаровые регулирующие клапаны Samson

Регулирующий клапан Fisher EZ

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!

Общий рейтинг

Оценка

Ниже представлено распределение всех оценокВсе отзывы